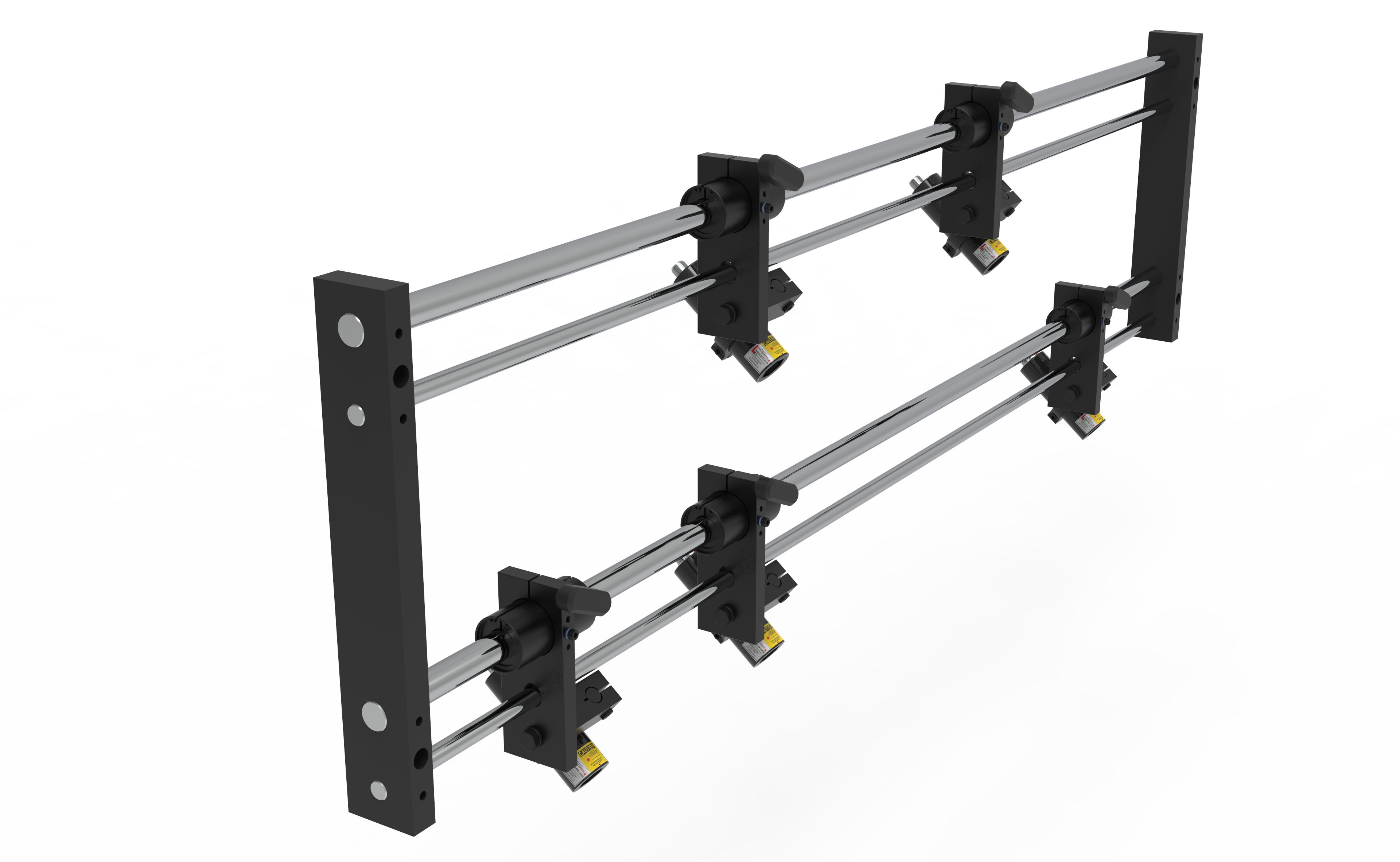

Gang Rip Saw Racks

Our gang rip saw laser mounting racks are versatile, with chrome steel that offers years of use with no wear or rust. Rip saw racks can be ordered fully outfitted or ordered minimally and added to as you add saws, accommodating up to 14 lasers. Setups are simple thanks to the innovative trolley design which provides easy repeatability, tool free adjustment, and laser lines as close as 3/4″.

SA-003

This three rail set comes with 3 sets of shafts at the standard length of 36″ *

SA-011 Trolley Purchased Separately**

Rail Set Includes:

3 bars 1/2″ chrome steel shaft

3 bars 3/4″ chrome steel shaft

2 end mounting brackets and setscrews

* 72″ maximum shaft length / length over 48″, extra charges will apply.

SA-003-Double

This two rail set comes with 2 sets of shafts at the standard length of 36″ *

SA-011 Trolley Purchased Separately**

Rail Set Includes:

2 bars 1/2″ chrome steel shaft

2 bars 3/4″ chrome steel shaft

2 end mounting brackets and setscrews

* 72″ maximum shaft length / length over 48″, extra charges will apply.

SA-003-Single

This single rail set comes with 1 set of shafts at the standard length of 36″ *

SA-011 Trolley Purchased Separately**

Rail Set Includes:

1 bar 1/2″ chrome steel shaft

1 bar 3/4″ chrome steel shaft

2 end mounting brackets and setscrews

* 72″ maximum shaft length / length over 48″, extra charges will apply.

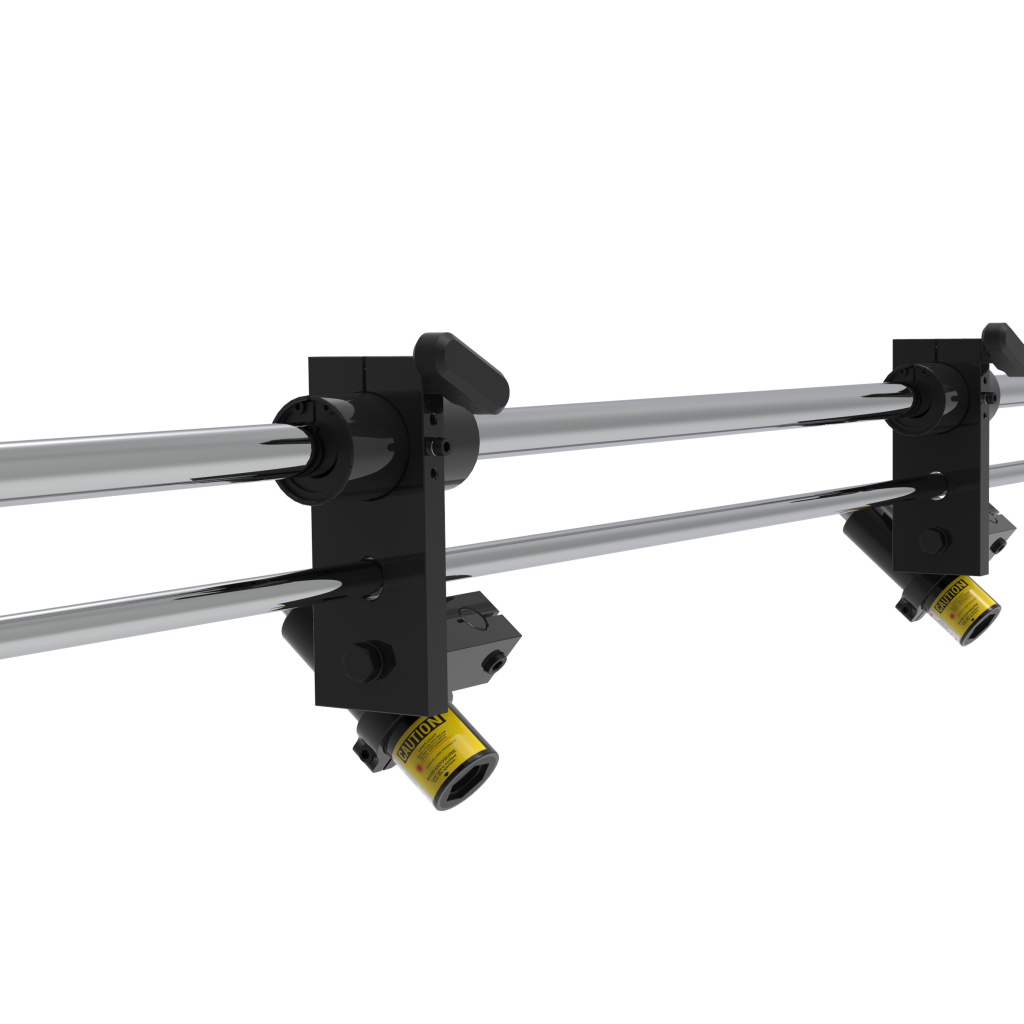

SA-011 Trolley

The SA-011 trolley is the heart of the rail system. Delrin ® bearings are retained with a snap ring, making bearing replacement painless. The sliding bracket is locked firmly onto the shaft via a thumbscrew, and of course the bracket provides all the adjustments required for aligning the lasers to your machine. (includes the SA-039 mounting ring assy.)