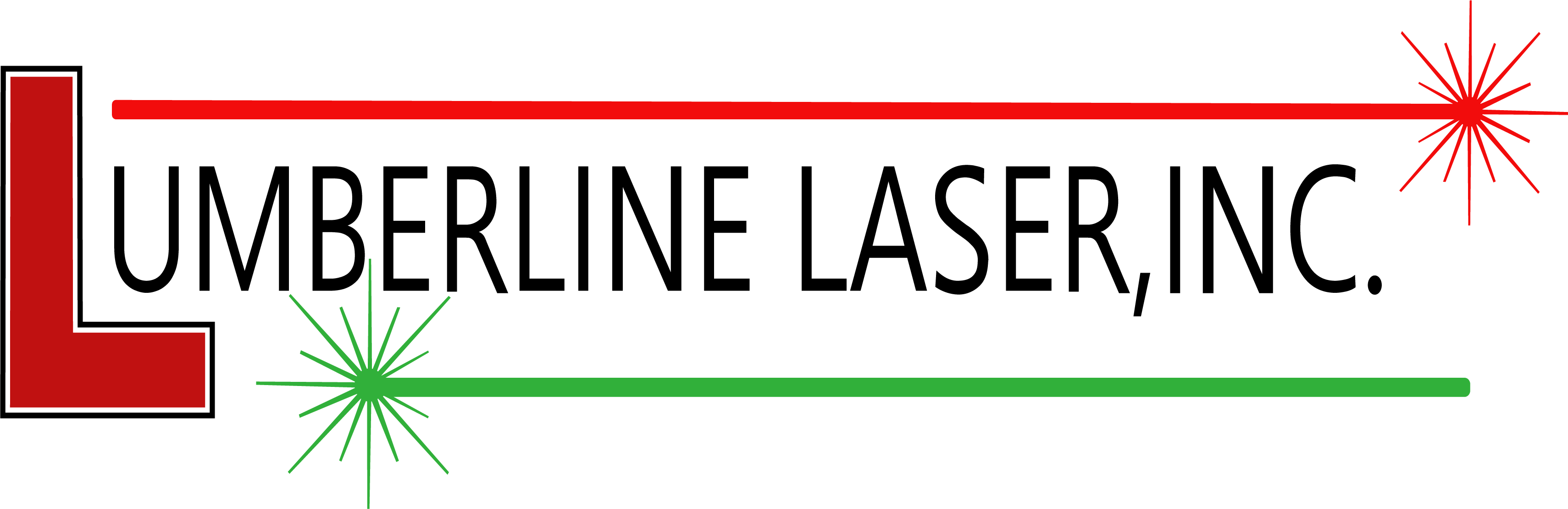

R Series Lasers

Power Supply Built into the Plug

Specifications

|

Power Levels |

*Lengths shown with typical shop lighting levels. High ambient light conditions may require a brighter unit. |

| Standard PSU | PT# SA-115 9’-10” cord Input: 100-240VAC Output: 5VDC 2A |

| Voltages | 3-9VDC *Supplied by the SA-115 PSU below |

| Amps | >150MA |

| Wavelength | RED 635nm GREEN 520nm |

| Warranty | 2 Years (limited) |

| Dimensions | Diameter 1.25” (31.75mm) Length 2.75” (69.85mm) *plus strain relief of the cordset |

| Documents | BROCHURE |

The R series laser is our most popular unit, powered by a remote style AC PSU (PT#SA-115) to supply the necessary 5VDC to the unit. As always, the unit fits all of our mounting hardware and movable systems.

Please ask us about any questions you might have regarding this unit.

Accessories

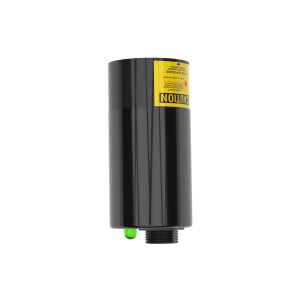

SA-008 Stationary Bracket

This unit is often used in conjunction with the SA-008 Stationary Bracket

Power Cable

SA-115 Power Cord with Built in Power Supply for R Series Lasers.

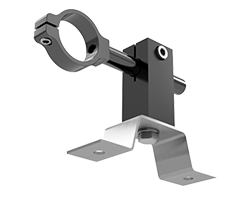

SA-111 ¾” shaft bracket

This unit is often used in conjunction with the SA-111 ¾” shaft bracket